- What inspired you to choose an apprenticeship?

Knowing that I was not going to be sat in a classroom all the time but gaining hands on experience and working with different people all whilst earning a wage. - How did you discover the Darchem apprenticeship program?

Through college/ government website. - What were your expectations before starting, and how have they compared to your actual experience?

Before starting, I expected to be challenged by the tasks within the apprenticeship and expected to not settle in straight away on the Darchem site. Compared to now, I have faced many challenges, which I have learnt a lot from. When I arrived at the Darchem site, I settled in and felt comfortable immediately. - What does a typical day look like for you in your role?

Working on different jobs alongside someone I can learn from and pick up new skills/ knowledge from. Usually carry out some welding and often given jobs to measure and mark out. - What skills have you learned so far, and how are they helping you in your work?

- Learned how to TIG weld which helps me in work because welding is involved with most jobs

- I’ve also learned how to safely operate different machines which are used in work

- I’ve learnt how to mark out metals of different sizes and shapes

- Can you share a project or task you’ve particularly enjoyed working on?

I enjoyed working on an exhaust support cowl for a marine application with Colin as it was a much larger job, and it helped to push me out of my comfort zone as I was carrying out a range of different activities on the job. I also enjoyed taking part in the Women in Engineering event at college. - How has the apprenticeship helped you grow personally and professionally?

It has helped me grow personally because I have gained confidence since starting the apprenticeship. It has helped me grow professionally as I have faced challenges, I have been able to learn and develop my skills from. - What has been the biggest challenge, and how did you overcome it?

Being patient when I don’t get something right first time. I over come this by taking my time and learning it’s okay if I don’t always Get things right first time, as long as I keep going and try again, because I always get there in the end. - What are your career goals, and how has the apprenticeship prepared you to achieve them?

My career goals are to push myself as far as possible and to work my way up the different job positions in the industry. My apprenticeship has prepared me for this by giving me the hands-on experience as well as allowing me to learn something new every day. - What advice would you give to someone considering an apprenticeship?

That an apprenticeship is not always easy, but it’s certainly worth it. You meet great people along the way and gain knowledge and experience that you couldn’t get from anywhere else. - What tips would you give to someone applying for an apprenticeship?

To know exactly what you are applying for and to do your research surrounding that apprenticeship. To make sure that the apprenticeship you apply for is something you can see yourself doing and enjoying in the future.

Apprenticeship Week Interview: Abigayle Neil

- What inspired you to choose an apprenticeship?

I like being hands on and learning different jobs within the workshop. - How did you discover the Darchem apprenticeship program?

I went to Hartlepool College of Further Education and joined a fabrication and weld course. Darchem then came into the college looking for apprentices which I got put forward for. - What were your expectations before starting, and how have they compared to your actual experience?

Before I started Darchem, I thought it would be a scary pace where you needed to know everything. However, I now know that making a mistake is okay and that we are here to learn, and everyone is very supportive and will help you if you need it. - What does a typical day look like for you in your role?

At the beginning of the day, we have a toolbox talk which is given by our team leader. We then get given a job to do/ continue a job, which we get help completing from the other workers/ tradesmen. - What skills have you learned so far, and how are they helping you in your work?

I have learned how to communicate within the workshop as well as gain fabrication and welding skills which I will continue to gain over time. - Can you share a project or task you’ve particularly enjoyed working on?

I enjoyed working on a job in Formula 1 motorsport as I got to use the press. As well as using the press, it was good to link the work I was doing and linking what they were used for and in what races. I gained a lot of new skills completing this job. - How has the apprenticeship helped you grow personally and professionally?

It has helped me grow as a person as I now know what I want to do. It’s gave me knowledge of how fabrication industries are and what’s expected of me. - What has been the biggest challenge, and how did you overcome it?

The biggest challenge I have overcome was being the only female in the workshop. However, everyone made me feel welcome and helped me if I needed it. - What are your career goals, and how has the apprenticeship prepared you to achieve them?

I would like to progress my skills as well as do a HNC course to improve my knowledge. The apprenticeship has helped me prepare for this as I now know what it’s like in industry and within the workshop. - What advice would you give to someone considering an apprenticeship?

I would advise you to go to college and do a course you are interested in and look at companies that offer apprenticeships in what you want to do. I also advise you to get stuck in and complete assignments and tests to the best of your ability. - What tips would you give to someone applying for an apprenticeship?

Research different companies to see what they all offer and what jobs they have available.

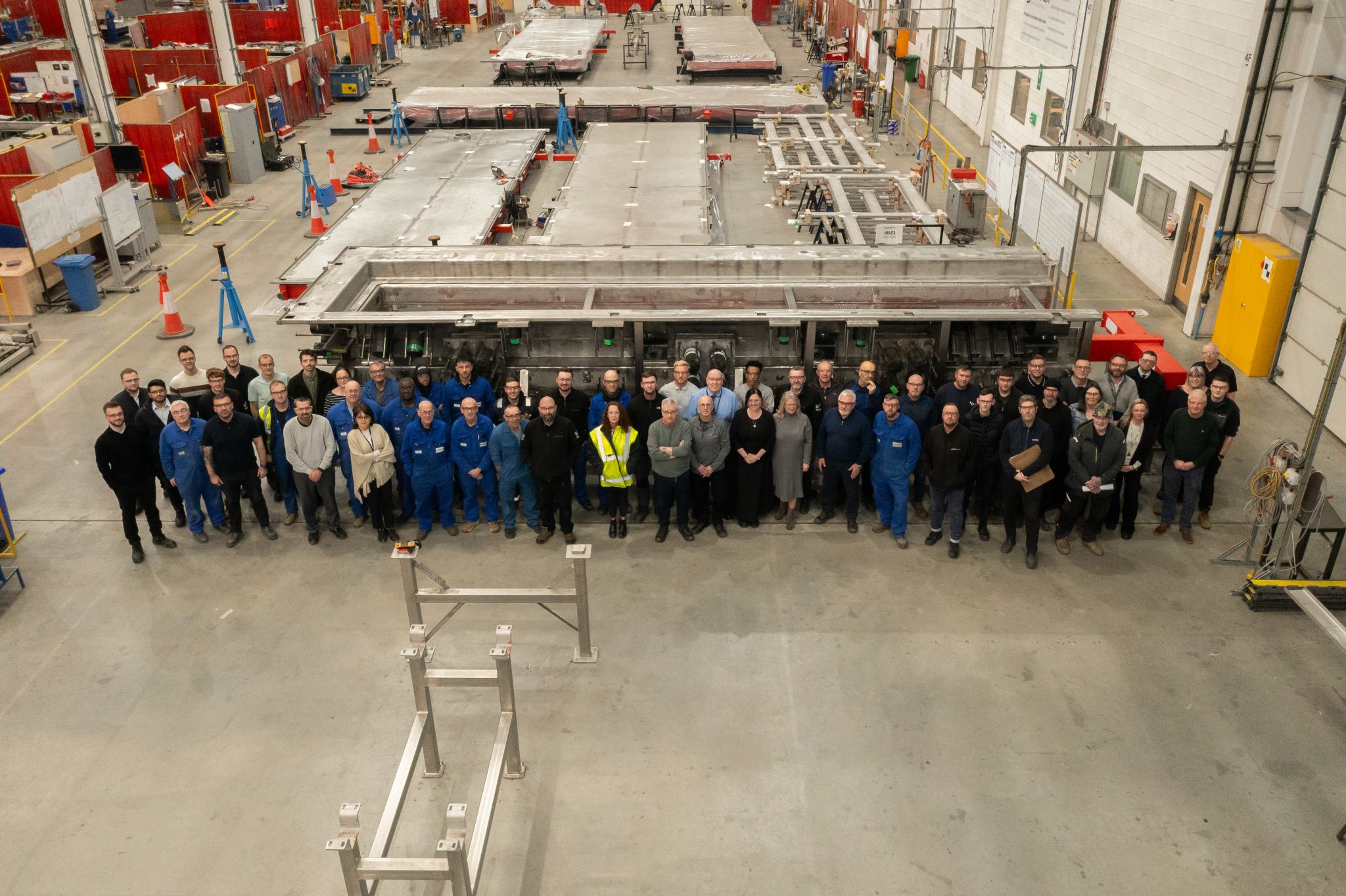

Darchem Engineering Celebrates Completion of Hinkley Point C Project

Having delivered the 1st Assembly in February 2022, Darchem Engineering Ltd Products Division reached a major milestone this week with the completion of the 10th & final Sluice Gate Frame for the Hinkley Point C Nuclear Power Station in Somerset!!

Darchem Honors the Women Shaping Our Future on International Women’s Day 2024

Having delivered the 1st Assembly in February 2022, Darchem Engineering Ltd Products Division reached a major milestone this week with the completion of the 10th & final Sluice Gate Frame for the Hinkley Point C Nuclear Power Station in Somerset!!

Darchem completes leadership development programme

Duis mollis, est non commodo luctus, nisi erat porttitor ligula, eget lacinia odio sem nec elit. Morbi leo risus, porta ac consectetur ac, vestibu lum at eros. Nulla vitae elit libero, a pharetra augue.

Darchem Launches New Website

Duis mollis, est non commodo luctus, nisi erat porttitor ligula, eget lacinia odio sem nec elit. Morbi leo risus, porta ac consectetur ac, vestibu lum at eros. Nulla vitae elit libero, a pharetra augue.

Darchem Engineering LTD delivers its 100,000 Thrust Reverser Blanket for the B737NG

Stillington, UK – This month Darchem Engineering will build and ship it`s 100,000th TRU Blanket for the B737NG. In 1991 Boeing initiated development of the more efficient, longer range Boeing 737-600 series Next Generation Aircraft. With Darchem’s turnkey service we were able to support this introduction using our in house design capability and testing to qualify thermal blankets for use on the largest commercial aircraft program in the world.

The first production blankets left Darchem in 1997 and have since gone through various design iterations fully supported by Darchem. Darchem`s design and operations team have seen changes in both design and volume and with our many years of experience are able to react quickly to support our customer needs. Darchem is proud to achieve this significant milestone and continues to supply high quality product on time to our customers.

Please visit us at www.darchem.com to learn more about our products and capabilities

About Darchem Engineering Ltd. –

Darchem Engineering Limited is a world class Engineering Company providing products and services to meet the needs of our customers for engineered solutions to high temperature/thermal engineering problems. Headquartered in the United Kingdom with over 60 years of experience, Darchem’s high-performance products can be found on aircraft, ships, oil rigs, performance motorcars, and in many other applications others worldwide. For more information please visit our website at www.darchem.com.